Taiichi Ohno’s Chalk Circle

Among many other things, Taiichi Ohno is known for his chalk circle (so called Ohno circle) and categorizing the seven wastes (muda). In the late 40’s, Ohno engineered the Toyota production system, which is mainly based on eliminating or reducing waste and inventory levels. He was brilliant in his approach on sharing his teachings, by engaging his managers and students in many exercises.

One of them was to stand in a circle (Ohno Circle). During this exercise, Ohno would take the manager, for example, to the shop floor, draw a chalk circle on the floor, then have them stand inside the circle and observe an operation. He would just say “Watch” and leave for a few hours...read full article.

.

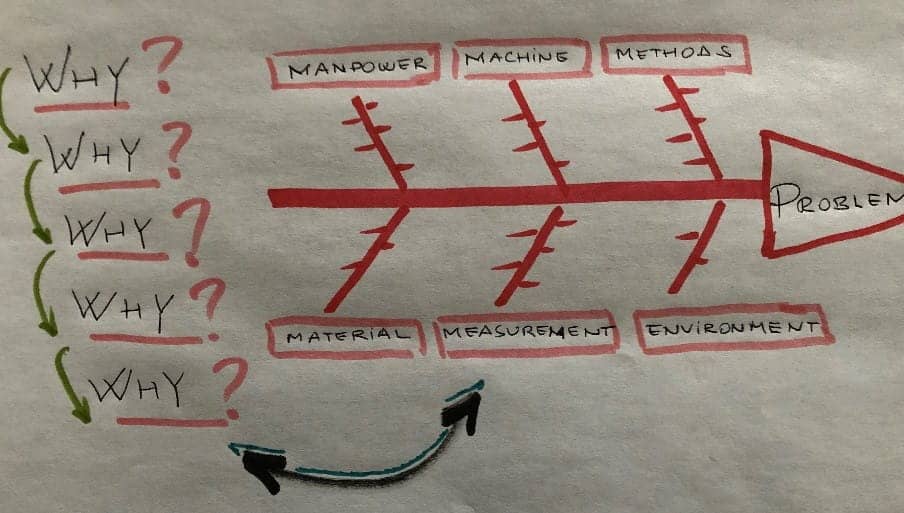

The 5 Whys Technique

The 5 Whys technique was developed by the “King of Japanese Inventors”, Sakichi Toyoda, the founder of Toyota Industries. Over the years, Toyoda invented a variety of textile industry devices, fueling systems for his machines and the famous power loom for which he implemented the Jidoka (automation with a human touch) principle…read full article.

.

Toyota Production System (TPS) Model

“A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods.”

Among a variety of models that depict the Toyota Production System, the one presented in the shape of a house with two pillars, Just-in-Time and Jidoka, is the most relevant.

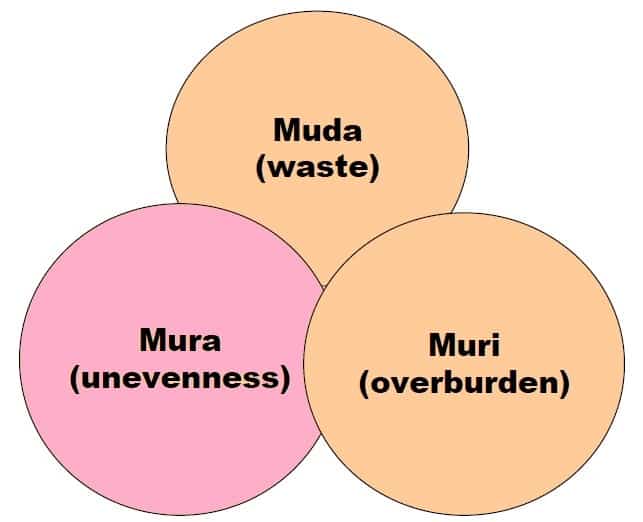

Just-in-Time as defined by Toyota is making only what is needed, when is needs and in the amount needed. By eliminating waste (muda, mura, muri) and producing quality products you can fulfill an order as quickly as possible. In other words, each process produces…read full article

.

The Toyota Way Second Edition

Summary of “The Toyota Way” 1st edition – 14 Management Principles

Principle 1: Base Your Decisions on a Long-Term Philosophy. This principle is the foundation of all subsequent principles. Think long term, even at the expense of short-term financial goals. Generate value for the customer and society...read full article.

.

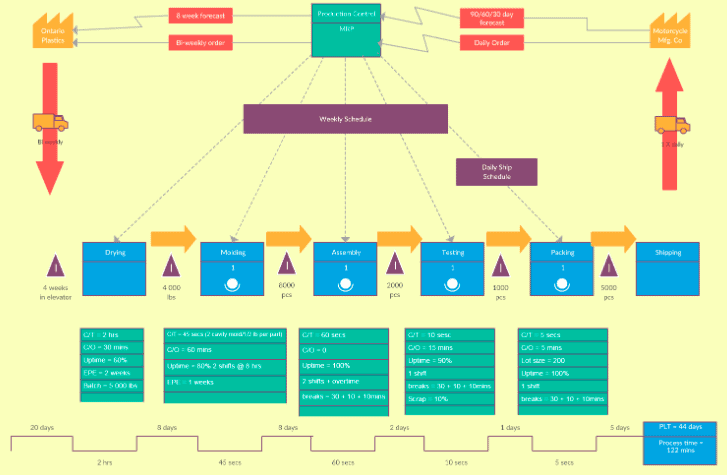

Value Stream Mapping for Product Development

A value stream map is a method of visualizing all steps needed to transform a customer request into a product or a service. Value stream mapping has been growing in popularity since the 90’s and became a fundamental tool to use when implementing Lean or Lean Six Sigma in any type of industry.

Even though the term “value stream” was first coined in early 90’s by James P. Womack and Daniel T. Jones, in their books “Lean Thinking” and “The Machine that Changed the World”, the concept can be traced back to Toyota…read full article

.

Toyota Kata Explained

Many companies around the globe studied Toyota Production System (TPS) and tried to adopt it within their organizations. However, after several years of struggle, implementing their version of TPS was often not very successful. So, Mike Rother went back to learn more and to study Toyota and its management approach for a few more years…read full article.

.

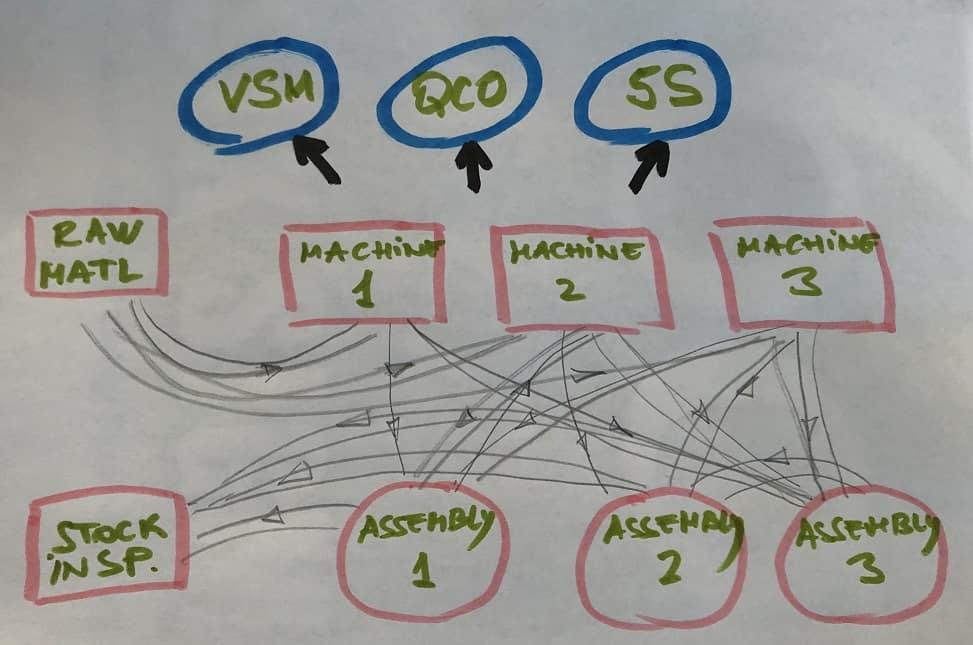

Spaghetti with some VSM, QCO and 5S

Spaghetti diagrams are mainly used to identify opportunities and to remove the waste of unnecessary motion or transportation. Spaghetti plots are a great way of visualizing the unnecessary complexity of a workflow and to identify improvement opportunities for expediting process flow. The spaghetti diagram is a great tool to use in conjunction with the Value Stream Mapping. It is also a great addition when implementing set in order (the second S of the 5S), as well as when implementing Quick Change…read full article.

.

What is Heijunka?

Most value streams produce a variety of products; therefore they face a choice of production mix and sequence. To prevent fluctuations in production, Toyota developed Heijunka and levels production by assembling a mix of models as part of each batch. This way, they level the production by volume, as well as by product type or mix and reduce the batch size as much as possible…read full article.

.

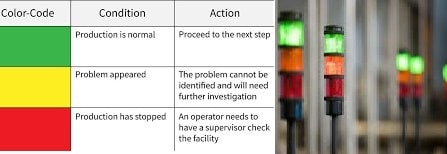

What is Andon – Lean Manufacturing

The term andon in Japanese means paper lantern and it could generally be interpreted as “light where to go”. An andon light or system is an integral part of Toyota Production System (TPS) and it is one of the most common visual management tools used in Lean. Andon lights are also the foundation for Jidoka (autonomation), which highlights the causes of problems because work stops immediately when a problem first occurs. It is a system that shows that an abnormal condition has occurred…read full article.

.

New Book Release Announcement: SigmaXL And Lean Six Sigma

The book our Senior Partner, Liviu Ibanescu, co-authored with Forrest Breyfogle, SigmaXL and Lean Six Sigma: A Guide to Improve Business Performance Metrics, will be available soon:

https://www.amazon.ca/gp/product/B0BXYGJPLF/

This book provides a comprehensive 9-step system that CEOs, presidents, general managers, executives, managers, leaders, practitioners, and others can use to resolve elephant-in-the-room management issues such as…read full article.