The term andon in Japanese means paper lantern and it could generally be interpreted as “light where to go”.

An andon light or system is an integral part of Toyota Production System (TPS) and it is one of the most common visual management tools used in Lean. Andon lights are also the foundation for Jidoka (autonomation), which highlights the causes of problems because work stops immediately when a problem first occurs. It is a system that shows that an abnormal condition has occurred and notifies maintenance, supervisors or managers of a potential quality or processing issue. Stopping the work momentarily and addressing the issue will save the organization from major and costly issues in the future.

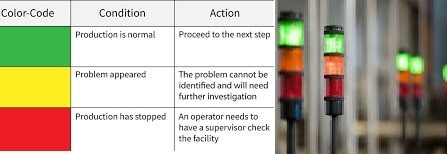

Typically, the andon is composed only of green, yellow and red lights and it shows whether the production takes place correctly or if a problem had appeared. The andon is basically a system of visual management that allows everyone to visualize right away when an issue arises and needs to be addressed immediately. Most common reasons for activating the andon (often called “pulling the andon cord”) are potential safety issues, defects found or tooling problems. The production is typically stopped until the issue has been contained and resolved. Implementing the andon empowers the operator or worker, and when needed, provides the means of stopping production to request urgent assistance.

This concept of empowering the worker or operator to stop production due to a suspected quality issue is often attributed to Dr. Edwards Deming and others who helped with Japan’s economic recovery and continuous improvement (Kaizen) implementation after WWII. Implementing the andon system and empowering the workers shows management willingness to establish a culture of quality by applying the PDCA (plan-do-check-act) cycle to continuously improve processes and products. Empowering workers also resonates nicely with Toyota’s and Lean’s principle of “Respect for People.”

The original alert developed by Toyota was activated by the operator manually, using a pull cord (andon cord). The newer version andon could be activated by push of a button or even automatically by the production equipment itself. The andon could also incorporate audio alarms with coded tones or tunes corresponding to various alerts, or text displaying a short description of the problem. Often, automated or semi-automated lines also include color coded stack light or a light tower on top of a machine. One or more lights indicate the current status of the machine.

In the Toyota plants, the assembly line has a fixed position stop. Therefore, when the andon cord is pulled, the line continues to move until it gets to the end of the particular work station. If nobody answers the andon or the issue is not resolved within the allotted time, then the production line stops. Typically, all Toyota andons have sound to signal the supervisor or technicians to look at the andon to see where the problem has occurred. An important advantage of andon systems is the fact that the team leader, supervisor or maintenance are not required to constantly monitor the production line, which in turn allows them to do other tasks until someone calls for assistance.

Therefore, when an andon is triggered, a light or alarm will come on when a problem is detected, either automatically by the machine or manually by the operator. This will be the trigger for the supervisor or the designated team to intervene right away at the location of the problem and address the issue.

The best andons are highly visual and can be seen from far away. All andon systems should have in place a clear reaction plan. When a stop work situation occurs, you should be able to perform a real-time root cause analysis, and quickly apply a solution. All andon calls should be tracked and the continuous improvement team should work on figuring out how to prevent problems from reoccurring.

Some of the most important Andon system benefits are:

-makes production and quality issues highly visible

-issues are noticed right away, addressed and production resumes quickly

-operators are empowered to take actions instead of waiting

-downtime is minimized by fixing the problem quickly

-overall cost is reduced by addressing the issues in a timely manner

.

Watch a short video: Toyota MotoMachi factory, Japan